Understanding Biocompatibility in Titanium Mesh Bone Grafts

Defining Biocompatibility in the Context of Titanium Mesh Bone Graft Biocompatibility

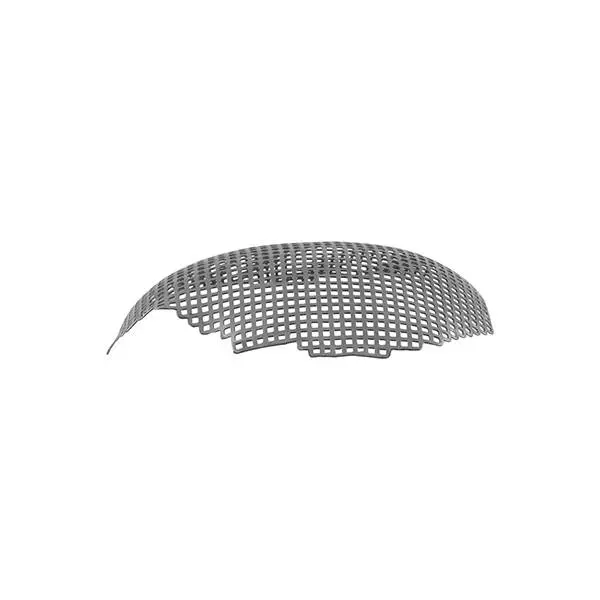

When we talk about biocompatibility, we're basically looking at whether a material can work alongside living tissues without causing problems. With titanium mesh used for bone grafts, the goal is getting these implants to blend in nicely with existing bone structures while keeping the body from rejecting them as foreign objects. Standards organizations like ISO 10993 have laid down guidelines focusing on things like toxicity tests, allergic responses, and how well materials hold up over time. Recent research from 2023 shows something interesting too: when titanium meshes undergo special surface treatments, they tend to form those pesky fibrous capsules around themselves about 67% less often than regular untreated ones. This suggests that how we engineer the material itself plays a big part in determining if it will be accepted by the body or not.

Biological Responses to Titanium-Based Biomaterials in Bone Regeneration

The corrosion resistant oxide layer on titanium (TiO2) helps bones grow back because it lets bone cells stick to the surface better than most materials. Studies show this happens around 80% of the time when the pores are just right. When the surface has tiny features similar to real bone tissue, something interesting happens. The body produces more alkaline phosphatase, which is basically nature's signal for new bone growth, about 45% more than on flat surfaces. But there's a catch. Some metals mixed into titanium alloys actually slow down healing. Aluminum and vanadium are particular problems here. Even very small amounts, as little as half a part per million, can stop bone cells from growing properly and cut their survival rate by roughly 22%, according to research published last year in the Journal of Orthopaedic Research.

The Role of Immune Response and Inflammation in Implant Integration

The way macrophages polarize makes all the difference for successful implants. When it comes down to it, M1 macrophages are basically troublemakers that cause inflammation, whereas their M2 counterparts actually help tissues heal and regenerate. Now here's something interesting about surface treatments like those hydroxyapatite coatings we've been talking about lately. These coatings can change the balance between M1 and M2 cells from around 3 to 1 toward a healthier 1 to 2 ratio just fourteen days after putting in an implant. And this shift isn't just theoretical stuff either; actual measurements show IL-6 levels drop by nearly 60%. What does this mean practically? Faster bone growth around the implant site. There's another factor worth mentioning too. Implants with pores connected at over 90% seem to keep those pesky neutrophils away better than others. Clinical studies back this up showing a reduction in peri-implantitis risk by roughly 40% when these interconnected pores are present.

Surface Modification Techniques to Enhance Titanium Mesh Biocompatibility

Chemical Treatments and Anodization for Improved Surface Energy and Corrosion Resistance

Acid etching and electrochemical anodization enhance surface energy and corrosion resistance in titanium mesh grafts. These processes create a stable, protective oxide layer that reduces metal ion release by 78% compared to untreated surfaces (Hashmi et al., 2023). Improved wettability also promotes protein adsorption, a crucial step for initiating bone regeneration.

Plasma Spraying and Biomolecule Coatings: Incorporating Growth Factors for Better Integration

Plasma-sprayed titanium combined with recombinant bone morphogenetic protein-2 (BMP-2) accelerates osteogenesis by 40% in preclinical models. Hydroxyapatite-biomolecule composite coatings further enhance integration by mimicking natural bone remodeling signals, creating a bioactive interface that improves biomaterial compatibility.

Nanotopography Design to Promote Cell Adhesion and Osteoblast Proliferation

Nanoscale patterning with groove depths of 20–50 nm increases osteoblast adhesion density by 3.1 times over smooth surfaces. This topographical control activates mechanotransduction pathways, boosting mineralization rates while preserving mechanical integrity for load-bearing applications.

Optimizing Pore Architecture for Effective Bone Ingrowth and Regeneration

Pore Size, Porosity, and Interconnectivity: Key Factors in Guided Bone Regeneration

Bone regeneration really hinges on three key structural factors: how big the pores are, their overall porosity, and whether they connect with each other. When pores measure around 200 to 500 micrometers, blood vessels can infiltrate better and osteoblasts work more effectively. On the flip side, smaller pores under 100 micrometers actually help minerals deposit more efficiently. For cancellous bone areas, materials need about 50 to 90 percent porosity, while cortical interfaces generally require much lower porosity levels between 5 and 30 percent to maintain both permeability and structural integrity. What makes all this work is when pores are fully connected throughout the material. This connectivity allows nutrients to flow through and waste products to exit properly. Research shows that materials with 85 to 90 percent interconnectivity see cells migrate twice as fast as those with disconnected pore structures, which matters a lot for successful tissue integration.

Ideal Structural Parameters for Mechanical Stability and Vascular Infiltration

If we want to avoid stress shielding issues, then titanium scaffolds need to match the stiffness characteristics of real bone tissue. The ideal gradient structures start around 1.6 to 3 gigapascals near where they touch the actual bone, gradually increasing up to about 10 to 20 GPa in areas that bear weight. This matches how bones naturally handle different loads across their structure. When it comes to design specifics, honeycomb shaped lattice patterns actually last about 40 percent longer under repeated stress tests compared to randomly placed holes. Some designs inspired by seashell spirals have shown impressive strength too, reaching over 95 megapascals when twisted. And interestingly enough, pores aligned along lengthwise directions help blood vessels grow through them much better than if they're scattered randomly everywhere. Studies using computer models suggest this can boost capillary network development by roughly two thirds.

Balancing Strength and Permeability in Porous Titanium Scaffolds

Triply Periodic Minimal Surfaces (TPMS) resolve the trade-off between mechanical strength and permeability through mathematically optimized geometries:

- Gyroid structures deliver 92% permeability at 70% porosity while maintaining 80 MPa compressive strength

- Diamond lattice designs provide 50% higher shear resistance than traditional foams at equivalent porosity

- Gradient TPMS scaffolds mimic trabecular bone’s adaptive stiffness, reducing micromotion risks by 73%

These biomimetic designs support hierarchical pore organization—macrochannels (300 µm) guide vasculature, while 10–50 µm surface textures amplify protein adsorption by 5–8 times compared to smooth titanium.

Advancements in 3D-Printed Titanium Mesh for Patient-Specific Bone Grafts

Precision Engineering of Titanium Mesh With Controlled Micro- and Macro-Architecture

With additive manufacturing, we can really control those tiny details in the material structure down to around 50 to 800 micrometer pores as well as the overall shape. This matters a lot when trying to get just the right balance between how strong something is mechanically at least 80 MPa compression strength and what the body needs for regeneration. Traditional methods like sintering or weaving just don't match up. The latest 3D printed versions have shown amazing results in tests from Biomaterials Advances last year, hitting nearly 94% interconnected pores. That means nutrients can spread evenly through the material and blood vessels can grow properly. The way these materials are built makes them work better inside the body because they reduce stress on surrounding tissues while still being rigid enough to span across defects where needed.

Customization Using CT and MRI Data for Anatomically Accurate Grafts

Custom titanium meshes made from CT and MRI scans before surgery can reach around 0.2 mm accuracy or better, which means they fit really well in complicated facial or spine repair cases. Looking back at data from 2024, doctors found that bones integrated about 22 percent faster when using these 3D printed meshes compared to ones shaped during surgery. The reason? Better contact between the bone and the mesh scaffold. Surgeons also save time on average about 40 minutes per case because there's no need for all those frustrating trial and error adjustments during operations.

Comparative Performance: Traditional vs. Additively Manufactured Titanium Meshes

Studies comparing traditional and additively manufactured titanium meshes reveal significant advantages for 3D-printed designs:

| Parameter | Traditional Mesh | 3D-Printed Mesh |

|---|---|---|

| Osseointegration Rate | 58% at 6 months | 82% at 6 months |

| Implant Failure Rate | 11% | 3.7% |

| Surgical Revision Rate | 18% | 6.2% |

Data: Journal of Orthopaedic Translation (2023)

Superior performance stems from fewer microfractures in printed lattices and surface roughness (Ra 12–18 µm vs. 6–9 µm) tailored for enhanced osteoblast adhesion.

Strategies to Enhance Osseointegration and Long-Term Clinical Success

Surface Functionalization for Stronger Titanium Mesh Integration with Host Tissue

Surface treatments such as SLA, which stands for Sandblasted Large-grit Acid-etching, actually create tiny rough spots on implants. This roughness makes the contact area between bone and implant about 40% bigger than what we see with smooth surfaces. Then there are these hydrophilic coatings that really help things stick together better. They make the surface more wettable, which is important because it helps those bone building cells called osteoblasts attach themselves much faster. Studies show they can speed up this process nearly threefold during the first three days after placement. The combination of these specially designed surfaces helps reduce movement between the bone and implant, something doctors look at closely when assessing how stable an implant will be right after surgery according to research published by Simão and colleagues back in 2022.

Hybrid Materials: Combining Titanium with Bioactive Ceramics Like Hydroxyapatite

Combining titanium with hydroxyapatite (HA) leverages the metal’s strength and HA’s osteoconductivity. Advanced coating methods allow precise control over HA crystallinity (30–70%), tuning degradation to match new bone formation. In diaphyseal defect models, composite grafts show 89% higher bone volume fraction at 12 weeks than pure titanium.

Clinical Evidence: Outcomes of Titanium-Hydroxyapatite Composite Grafts

According to a recent 2024 study looking at over 2,000 cases, titanium-HA composite meshes have shown impressive results with around 96.3% survival after five years. That's significantly better than regular uncoated titanium which only manages about 84.7% in tricky bone situations. What makes these composites so good? Well, they contain a calcium phosphate layer that actually helps blood vessels grow more effectively. Researchers noticed nearly half again as much vascular growth at the six month mark compared to controls. For patients dealing with severe jawbone loss specifically, these graft materials work really well. Clinical trials showed an average gain of approximately 2.1 millimeters vertically in the upper jaw area thanks to ongoing signals that stimulate new bone formation over time.

Key Achievements

| Parameter | Standard Titanium | Titanium-HA Composite | Improvement |

|---|---|---|---|

| Bone Contact Area (%) | 58.4 | 82.1 | +40.6% |

| Time to Osseointegration | 16 weeks | 9.5 weeks | -40.6% |

| 5-Year Survival Rate | 84.7% | 96.3% | +11.6% |

This data-driven approach to surface engineering and material science is redefining titanium mesh bone graft biocompatibility while addressing both biological integration and long-term mechanical performance requirements.

Frequently Asked Questions (FAQ)

What is biocompatibility and why is it important for titanium mesh bone grafts?

Biocompatibility refers to the ability of a material to perform with an appropriate host response in a specific application. For titanium mesh bone grafts, it ensures that the implants blend well with existing bone structures and avoid rejection by the body, facilitating successful integration.

Why do surface treatments on titanium meshes matter?

Surface treatments enhance the physical and chemical properties of titanium meshes, improving corrosion resistance, protein adsorption, and promoting better tissue integration. These treatments can significantly reduce the formation of fibrous capsules and inflammation around implants.

How does pore architecture influence bone regeneration?

The size, porosity, and interconnectivity of pores in titanium scaffolds are crucial for effective bone regeneration. Proper pore architecture allows blood vessel infiltration, nutrient flow, and waste removal, which are vital for efficient tissue integration.

What are the advantages of 3D-printed titanium meshes over traditional designs?

3D-printed titanium meshes offer higher osseointegration rates, fewer implant failures, and lower surgical revision rates compared to traditional meshes. Their precision and tailored micro-architecture facilitate better fit and faster bone integration.

How do titanium-hydroxyapatite composites enhance graft performance?

Titanium-hydroxyapatite composites combine strength and osteoconductivity, improving bone volume and vascular growth. They have shown significantly higher survival rates and better integration in clinical trials.

Table of Contents

- Understanding Biocompatibility in Titanium Mesh Bone Grafts

- Surface Modification Techniques to Enhance Titanium Mesh Biocompatibility

- Optimizing Pore Architecture for Effective Bone Ingrowth and Regeneration

- Advancements in 3D-Printed Titanium Mesh for Patient-Specific Bone Grafts

- Strategies to Enhance Osseointegration and Long-Term Clinical Success

-

Frequently Asked Questions (FAQ)

- What is biocompatibility and why is it important for titanium mesh bone grafts?

- Why do surface treatments on titanium meshes matter?

- How does pore architecture influence bone regeneration?

- What are the advantages of 3D-printed titanium meshes over traditional designs?

- How do titanium-hydroxyapatite composites enhance graft performance?

EN

EN

FR

FR

ES

ES

AR

AR