The Critical Time-Sensitivity of Just-in-Time Logistics for Emergency Trauma Kits

Why the 15-Minute Golden Window Dictates Inventory Positioning and Lead-Time Tolerance

When it comes to trauma care, those first 15 minutes after injury are often called the "golden window" and they really do make all the difference for patients needing rib fixation. Because of this short window, hospitals have started placing emergency trauma kits right next to operating rooms instead of relying on warehouse systems that just take too long to get stuff there. The whole point of just-in-time logistics is to keep everything moving fast enough so kits can be deployed within seven minutes max. Standard medical supplies might handle some delays, but rib fixation parts? They don't cut any slack at all. A recent study from Johns Hopkins back in 2023 showed something pretty scary actually - every three minute wait for rib repair tools raises the death rate by 11%. That's why having small warehouses strategically located close to operating rooms isn't just nice to have anymore. It's absolutely necessary if we want to stop wasting precious hours waiting for equipment from distant storage areas.

How Surge-Driven Demand Spikes Overwhelm Traditional Replenishment Cycles

Mass casualty events trigger demand volatility that exposes fundamental weaknesses in conventional supply modelsâemergency departments often face sudden 300â400% surges in rib fixation component usage. These spikes reveal three systemic failures:

- Forecast dependency: Historical data is irrelevant during black-swan events

- Batch processing: Weekly replenishment cycles leave hospitals vulnerable during 72-hour crisis windows

- Buffer inventory costs: Static safety stocks of specialized plates and screws expire unused 34% of the time (EMRA 2024)

Dynamic JIT logistics resolves this fragility. AI-driven consumption triggers initiate instant replenishment from nearby hubs, while RFID-enabled real-time usage tracking cuts restocking lead times to under 2 hoursâpreserving supply chain resilience when it matters most.

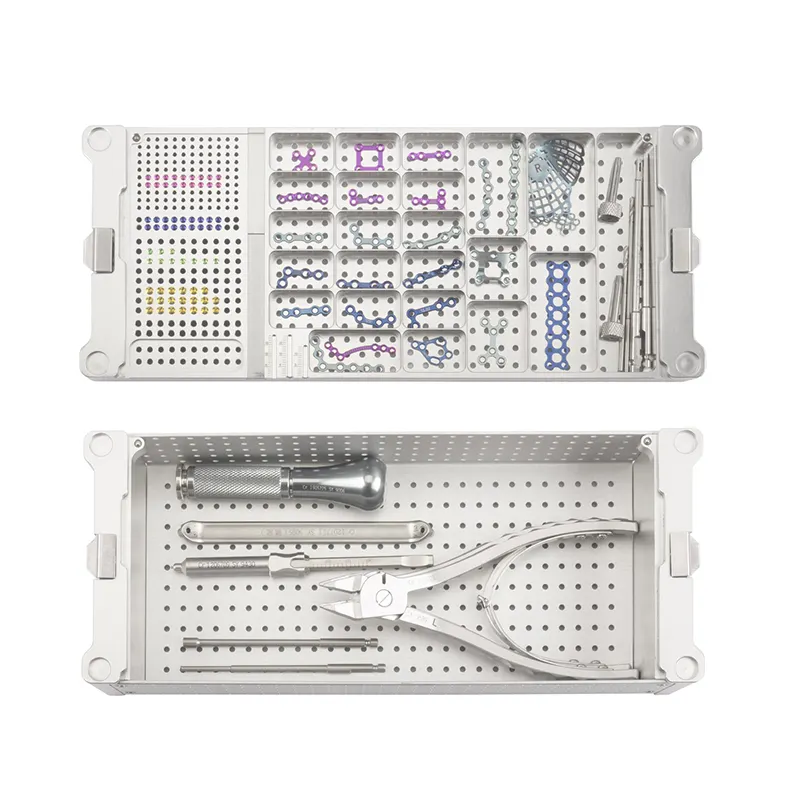

Ensuring Kitting Accuracy for Rib Fixation Components Under JIT Constraints

Managing High Component Variability: 7â12 Patient-Specific Configurations per Trauma Case

Rib fixation demands exceptional kitting precision: Orthopedic Trauma Association (2023) data shows 7â12 patient-specific configurations are typical per thoracic trauma case. Traditional batch kitting falters hereâ43% of cases require last-minute component substitutions due to intraoperative anatomical surprises, delaying OR readiness by 15+ minutes. JIT systems meet this challenge through:

- Pre-surgical digital mapping of implant dimensions (e.g., curved plates vs. straight struts) to CT scans

- AI-guided pick-to-light carts that reduce human error during urgent assembly

- Barcode and RFID cross-checks that validate hardware compatibility before OR delivery

This layered verification prevents catastrophic mismatchesâsuch as an omitted locking screwâthat can compromise stabilization in time-critical procedures.

Pre-Assembled vs. Modular Kitting: Trade-offs in Readiness, Shelf Life, and JIT Feasibility

Hospitals weigh two primary kitting strategies for rib fixation components:

| Approach | Readiness Time | Shelf Life | JIT Compatibility |

|---|---|---|---|

| Pre-assembled kits | â2 minutes | 18 months | Low (static inventory) |

| Modular systems | â5 minutes | Indefinite | High (dynamic pooling) |

The problem with those ready-made surgical kits is they save time upfront but actually cost hospitals a fortune down the road. We're talking about around $740,000 wasted each year at Level 1 trauma centers because stuff just sits there until it expires. That's according to Ponemon's 2023 report. A better approach? Modular kits that wait until the actual surgery is confirmed before putting everything together. This lets staff see exactly what's available in real time, cutting down on waste and making it easier when emergencies pop up unexpectedly. Sure, setting up takes about three extra minutes, but studies show these systems cut down on mistakes by nearly two thirds in situations where parts vary a lot. The trick works especially well with items that don't need special storage conditions, such as titanium screws. Things that must stay chilled still get their own pre-packed sets though.

Real-Time Inventory Visibility: Enabling Reliable JIT Delivery Across Hospital Systems

RFID and Edge-Computing Solutions for End-to-End Traceability from Warehouse to OR

When RFID tags work alongside edge computing systems, they give hospitals critical visibility over where emergency trauma kits actually are at any given moment. These kits send out their location info while moving through different stages like warehouses, sterile storage areas, and ultimately reaching operating rooms. Local edge devices handle this information instead of relying on distant cloud servers, so there's no lag time. The quick response helps prevent running out of supplies during unexpected trauma situations. According to NHTSA stats, about two thirds of chest injuries happen without warning. When inventory drops below safe levels, automatic alerts go off. For complex rib fixation kits that need around twelve customized parts, RFID scans confirm every plate and screw matches what surgeons need before sending them to surgery. The technology keeps track of environmental factors too, watching for temperature changes that might compromise sterility. Manual stock checks take forever sometimes delaying treatment by forty whole minutes as noted in a recent Journal of Trauma Nursing study. These smart systems ensure timely delivery requirements stay met throughout entire hospital networks.

Last-Mile Execution: Aligning JIT Logistics with Unpredictable Surgical Scheduling

Navigating OR Disruptions: 68% of Thoracic Trauma Cases Are Unscheduled (NHTSA Data)

About 68% of chest injuries come through emergency doors with no warning at all according to NHTSA data, which makes fixed delivery times practically impossible in operating rooms where things are always changing. Getting supplies to where they need to go depends on people working together in real time across departments rather than sticking to predetermined routes. When parts for fixing broken ribs arrive late, patients can miss their critical 15 minute treatment window completely. Top hospitals use smart routing systems that actually move medical kits away from unexpected problems like sudden surgeries popping up, missing equipment, or delays cleaning operating rooms. Special packaging that keeps items stable at room temperature plus tracking systems let staff know exactly where each kit is at any moment even as plans change. The bottom line? Matching just-in-time deliveries with what's happening right now in surgery instead of relying on old fashioned schedules ensures we're ready to save lives despite all the chaos going on day after day.

FAQ

What is the "golden window" in trauma care?

The "golden window" refers to the critical first 15 minutes after an injury, where timely intervention can make a significant difference in the patient's outcome.

Why are just-in-time logistics important for emergency trauma kits?

Just-in-time logistics are vital because they ensure quick availability of critical medical supplies, like rib fixation parts, within the golden window, improving survival rates.

What are the advantages of modular kitting over pre-assembled kits?

Modular kitting reduces waste and allows for real-time adaptability to patient needs, cutting down on unnecessary costs and errors compared to pre-assembled kits.

Table of Contents

- The Critical Time-Sensitivity of Just-in-Time Logistics for Emergency Trauma Kits

- Ensuring Kitting Accuracy for Rib Fixation Components Under JIT Constraints

- Real-Time Inventory Visibility: Enabling Reliable JIT Delivery Across Hospital Systems

- Last-Mile Execution: Aligning JIT Logistics with Unpredictable Surgical Scheduling

EN

EN

FR

FR

ES

ES

AR

AR