Define Key Benchmarking Criteria for Distal Humerus Plates

Anatomical Fit and Pre-Contoured Design Accuracy

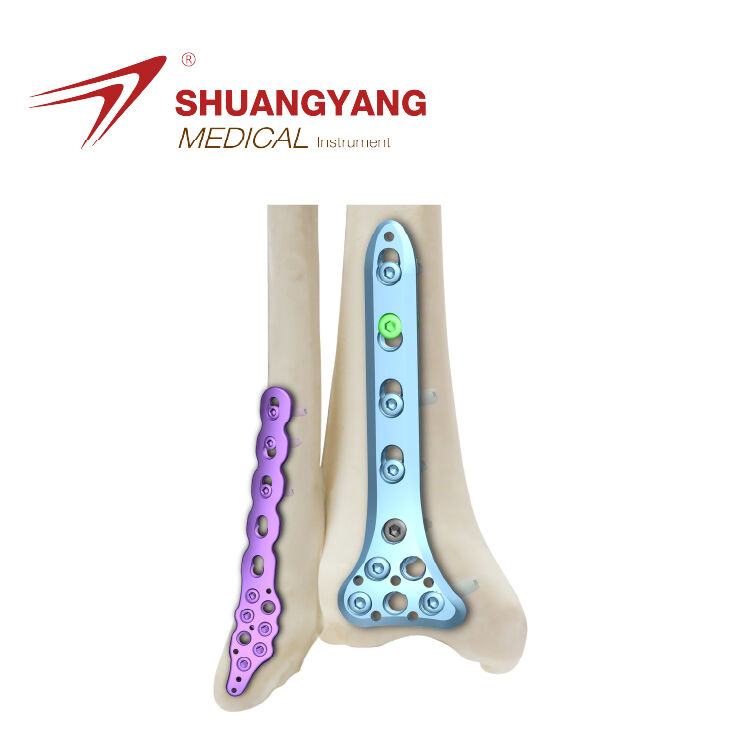

Getting the shape right matters a lot when fixing fractures in the lower part of the upper arm bone. Surgical plates need to match how the back outer part of this bone naturally curves so they don't irritate surrounding tissues and allow screws to be placed properly. Studies looking at real world cases indicate that if a plate doesn't fit within about 1.5 millimeters of what's normal for that area, there's around a 22 percent higher chance the surgery will need to be redone later on account of problems like bones rubbing together incorrectly or not being aligned properly. Most modern implant systems now feature specially shaped edges and adjustable locking mechanisms that let surgeons adapt to differences between patients based on factors like their age group, gender, and ethnic background.

Biomechanical Performance: Angular Stability and Fatigue Resistance

The ability to maintain angular stability during repeated loading and resist fatigue failure makes a big difference in biomechanical performance. Studies show that these special 5 degree conical locking threads keep about 98 percent of their original torque strength even after going through 10,000 load cycles. That's way better than regular thread designs which only manage around 84%. When it comes to bones affected by osteoporosis, fatigue resistance becomes really important. Plates designed with improved cross sections can handle roughly 15% more twisting force before breaking down according to tests done recently in Scientific Reports. And this matters because when there's too much movement at the fracture site, specifically over 500 micrometers, the chances of getting a nonunion increase almost fourfold in weaker bones.

Compare Synthes Distal Humerus Plate Specifications Against Top Competitors

Material Science: Titanium Alloy (Ti-6Al-4V) vs. Stainless Steel Trade-offs

The Ti-6Al-4V titanium alloy stands out when it comes to how well it works inside the body, resists rust, and handles repeated stress better than regular stainless steel these days. These qualities are really important for implants that need to last a long time in tough spots such as the distal humerus area of the arm. Recent research from 2023 showed that titanium plates can handle about 15 percent more stress cycles before breaking down, which actually helps reduce problems where bones don't heal properly after surgery on weakened areas. Stainless steel still has its place in situations where budget matters most, but top companies like Synthes have started using special vacuum arc melting techniques to cut down on tiny flaws in their titanium parts while making sure everything stays structurally sound across different applications.

Locking Mechanism Architecture: Thread Engagement and Insertion Torque Consistency

Getting consistent thread engagement depth really matters for proper fixation when dealing with different bone qualities. The Synthes plates manage to maintain about 92% insertion torque consistency even when screws are placed along various paths, according to tests done independently in 2025. Looking at competitors though, their systems show torque variations of up to 20% when tested under similar bone density conditions. This kind of inconsistency tends to lead to screws coming loose sooner than expected. Newer Synthes designs feature improved thread shapes that spread out shear forces better across the implant site. This helps reduce the stress shielding problem that was common in older versions of these devices. Clinical data from multiple centers actually shows that this design improvement correlates with roughly 8% fewer revision procedures needed down the road.

Assess Real-World Clinical Validation and Surgeon Preference Data

Peer-Reviewed Outcomes: Nonunion Rates and Revision Surgery Incidence

Clinical validation needs more than just numbers from lab tests it requires solid evidence from actual medical research. Recent publications show that when doctors use distal humerus plating systems, about 8 out of 100 patients experience nonunion issues, sometimes going up to 15%. Systems that perform better tend to have good angular stability, fit properly in the bone anatomy, and feature locking mechanisms that work well together according to findings in the Journal of Orthopaedic Trauma last year. Looking at how often these systems need to be fixed gives us a pretty accurate picture of their real world effectiveness. When a system keeps revision surgeries below 10%, this generally means it's technically advanced enough and fits into how surgeons actually work during operations.

KOL Insights and Multicenter Preference Surveys (2022–2024)

What surgeons prefer still sends strong signals through the market, especially in trauma cases where getting procedures done quickly without complications matters most for adoption rates. Surveys from multiple centers across 2022 to mid-2024 show around 70% of orthopedic trauma doctors look at angular stability first and want proof that complications drop after surgery before picking distal humerus implants. The 2023 AAOS report backs this up, pointing out that implants showing under 5% need for revisions in real world testing across different hospitals tend to catch on faster among practitioners. This tells us that actual results from these studies carry more weight than just what manufacturers put on their product specs.

Synthesize Findings into Actionable Competitive Positioning

Turning benchmark data into actual strategy means zeroing in on what really matters clinically while also fixing what's missing. Take the Synthes distal humerus plate for instance. It stands out when it comes to angular stability during repeated loading tests and delivers consistent torque even in tricky bone conditions. These are exactly the kinds of strengths that need front and center attention in our educational materials and value propositions. When we look at surgeon preference data showing widespread acceptance of certain pre-contoured designs, those become must-highlight features in all our marketing collateral and operating room support tools. Titanium's resistance to fatigue isn't anything new across the board, but Synthes has something extra going for it. Our manufacturing process using vacuum arc melting gives us a solid edge over generic competitors. What matters most though? Our research and development efforts need to tackle the problems surgeons actually face. Multicenter surveys show revision rates still hover around 8-10%, so we need to work on improving those locking interfaces and broadening our range of anatomical solutions. This kind of data driven approach doesn't just create better products, it turns technical specs into real business growth opportunities in the trauma plating space.

FAQ

What is the importance of anatomical fit for distal humerus plates?

An accurate anatomical fit ensures that the surgical plates do not irritate surrounding tissues and allow screws to be placed properly, which reduces the risk of surgery needing to be redone.

How do distal humerus plates perform in terms of angular stability and fatigue resistance?

Distal humerus plates with special conical locking threads provide high angular stability and retain a high percentage of their original torque strength even after numerous load cycles, which is crucial for bones affected by osteoporosis.

Why is titanium alloy preferred over stainless steel for distal humerus plates?

Titanium alloy, such as Ti-6Al-4V, performs better in terms of biocompatibility, corrosion resistance, and fatigue resistance, making it a preferred material for implants that endure stress and need to last long.

What advantages does Synthes provide in their distal humerus plates?

Synthes plates offer improved thread designs that help distribute shear forces, maintain consistent torque, and reduce stress shielding, leading to fewer required revision surgeries compared to competitors.

What factors influence surgeon preference in distal humerus implants?

Surgeons prioritize angular stability and evidence of decreased complications post-surgery when choosing distal humerus implants. Real-world test results and revision rates play a significant role in their decision-making.

Table of Contents

- Define Key Benchmarking Criteria for Distal Humerus Plates

- Compare Synthes Distal Humerus Plate Specifications Against Top Competitors

- Assess Real-World Clinical Validation and Surgeon Preference Data

- Synthesize Findings into Actionable Competitive Positioning

-

FAQ

- What is the importance of anatomical fit for distal humerus plates?

- How do distal humerus plates perform in terms of angular stability and fatigue resistance?

- Why is titanium alloy preferred over stainless steel for distal humerus plates?

- What advantages does Synthes provide in their distal humerus plates?

- What factors influence surgeon preference in distal humerus implants?

EN

EN

FR

FR

ES

ES

AR

AR