What Is Lot Traceability in Medical Devices?

Definition and Core Concepts of Lot Traceability

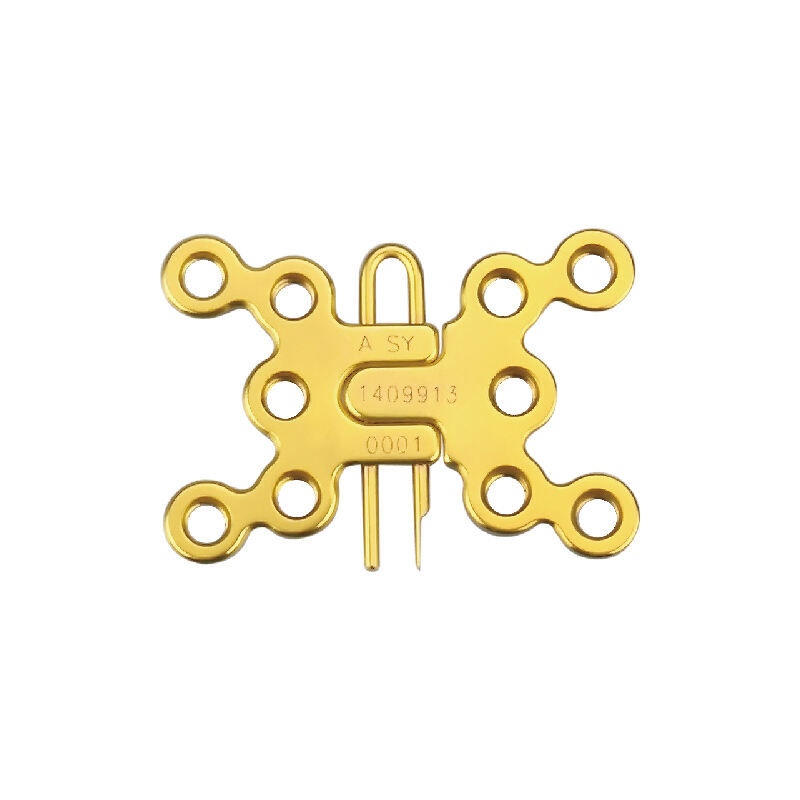

Tracking medical devices through their production lots means following items made from the same materials using similar processes at around the same time. Every batch gets its own special number so companies can keep detailed records starting when materials arrive all the way until products reach customers. This kind of detailed tracking matters a lot in industries where regulations are strict because keeping batches consistent actually impacts how safe patients stay. Take titanium implants for instance. When problems with how well they work inside the body show up, good traceability systems let manufacturers find out which specific batches might be affected much faster than waiting weeks. This helps avoid big scale recalls and keeps everything in line with standards like ISO 13485 across different countries. At its core, effective lot traceability depends on several key parts working together including assigning unique numbers to each batch, keeping digital records about where materials came from, and setting up alerts whenever something goes off track during production.

Importance of Batch and Serial Number Tracking

Tracking batch numbers and serial numbers plays different but important parts when it comes to managing risks. Batch numbers basically group together all the devices made under similar manufacturing conditions, which makes it easier to handle problems that affect whole groups of products, such as when certain sternum plates start fracturing or showing signs of corrosion over time. Serial numbers go one step further by giving each individual device its own unique identity, especially crucial for those high risk implants that need to meet UDI standards. When patients need to be notified about urgent recalls, these serial numbers make sure only the affected units get flagged. According to recent recall data from 2023, companies using both systems see around a 63% drop in their legal liabilities while being much better prepared for audits. Beyond just risk management, this dual approach actually works wonders for optimizing how medical devices move through the supply chain. Less wasted inventory and proper first-in-first-out distribution becomes possible, particularly important for those sterile surgical kits where timing matters most.

Regulatory Requirements for Medical Device Traceability

FDA UDI Rule and Global Standards (EU MDR, ISO 13485)

Since 2013, the FDA has been pushing for its Unique Device Identification rule which basically requires medical device manufacturers to track products through permanent identifiers either in barcodes or RFID tags. Around the world, similar requirements exist too. The EU Medical Device Regulation from 2017 along with ISO standard 13485:2016 are making waves especially when it comes to monitoring implants after they've been sold, think things like titanium plates used in spinal surgeries or those sternum fixation devices. Not following these rules can get pretty expensive though. Companies caught violating FDA regulations face an average fine of half a million dollars each time according to 2023 data, and that doesn't even touch on losing valuable market access or damaging their reputation among healthcare providers.

Compliance Benefits and Audit Preparedness

Having a solid traceability system makes regulatory audits much easier since all the device history records and supply chain information is right there when needed. Companies report cutting their recall expenses around 40 percent because they can find problem batches so quickly. The time spent getting ready for those ISO 13485 audits drops about 60 percent as well thanks to reports that generate themselves automatically. Looking at it from another angle, these systems show real commitment to patient safety over time. When regulators see this kind of ongoing attention to detail, it builds confidence across the board with everyone involved including doctors, hospitals, and ultimately the people who need medical devices most.

How Lot Traceability Enhances Patient Safety and Recall Management

Rapid Identification of Affected Devices During Recalls

When it comes to product recalls, good lot traceability changes everything from just reacting to problems into actually stopping them before they happen. Manual tracking can drag on for weeks sometimes, but automated systems spot bad batches within a day at most. And this really matters when people's health is on the line. Take the recent sternum plate situation as an example. With accurate lot numbers, surgeons could check if implants were safe right before surgery, so nobody ended up with something broken inside their body. The FDA reports show these faster response times cut down how many patients get exposed to faulty medical devices by around two thirds compared to old school methods that took forever to track things down.

Reducing Risk and Liability Through Precision Tracking

When companies track products at the granular level instead of doing broad recalls, they save money and resources. Imagine finding out there's a problem with titanium implants from just one production line. Instead of pulling every single implant off shelves nationwide, manufacturers can target only what needs attention. This approach saved around $740,000 in unnecessary losses according to Ponemon Institute research back in 2023. Courts actually take notice when businesses maintain detailed records too. Judges see this kind of meticulous tracking as proof that companies care about safety standards. As reported in the Journal of Medical Device Regulation last year, firms with good traceability systems faced 45% fewer liability claims compared to those without proper documentation. It makes business sense and protects patients at the same time.

| Tracking Method | Recall Duration | Cost Impact | Patient Risk Reduction |

|---|---|---|---|

| Manual | 2–4 weeks | High | 30% |

| Lot Traceability | <24 hours | Low | 85% |

Implementing an Effective Lot Traceability System

Leveraging Barcode and RFID Technologies

Tracking lots in medical devices today depends heavily on automatic identification systems. GS1 DataMatrix barcodes along with RFID tags are used to put all those important details like UDIs, batch numbers, expiry dates, and serial numbers right onto the actual devices themselves plus their packaging materials. The good news is these tech solutions cut down on mistakes from people entering data manually something like around 95% of the time, and they also speed things up throughout both production lines and shipping operations. When it comes to places where traditional barcodes just won't work, RFID really shines. Think about sterile environments or situations where there's no clear view between scanner and item, like when dealing with surgical instruments packed inside trays for operating rooms. That's where RFID becomes so valuable because regular barcodes simply aren't practical anymore.

Integrating Traceability into Supply Chain and ERP Systems

Getting full visibility throughout the supply chain means connecting with ERP systems and warehouse management tools. Automatic sharing of traceability information between different platforms makes possible real time updates about batch statuses, helps trigger recalls when needed, and simplifies compliance reports required for FDA inspections and EU Medical Device Regulation checks. Such system integration can cut down on the costs associated with managing implant recalls by around two thirds. What's more, it creates one consistent reference point for tracking products everywhere from manufacturing sites to distribution centers across international borders.

Best Practices for Data Accuracy and System Validation

Reliability hinges on disciplined validation and operational discipline:

- Standardized lot numbering formats that embed date, facility, and shift information

- Automated expiration alerts to enforce FEFO (First Expired, First Out) protocols

- Routine reconciliation of digital records against physical inventory

- Ongoing staff training on UDI compliance and documentation integrity

Regular ISO 13485 gap assessments ensure systems remain audit-ready—and minimize both recall scope and enterprise risk.

Frequently Asked Questions (FAQs)

What is lot traceability?

Lot traceability involves tracking medical devices through their production lots, which are groups of items made from the same materials using similar processes at about the same time. This helps in maintaining safety and compliance with regulations.

Why is batch and serial number tracking important in medical devices?

Batch numbers group devices made under similar conditions, aiding in managing risks associated with entire groups. Serial numbers provide unique identification for each device, crucial for high-risk implants requiring UDI standards.

How does lot traceability affect regulatory compliance?

Lot traceability aligns with standards like FDA UDI, EU MDR, and ISO 13485, reducing the risk of fines, and facilitating easier audits by providing comprehensive device history records.

How do barcodes and RFID technologies aid in lot traceability?

These technologies allow for efficient tracking by automating data entry, minimizing errors, and enhancing speed in production and distribution.

What are the benefits of integrating traceability into ERP systems?

Integration allows real-time updates, streamlined recall processes, simplified compliance reporting, and consistent tracking across international distribution channels.

EN

EN

FR

FR

ES

ES

AR

AR