Why Predictive Maintenance Is Critical for Rib Plate Surgical Trays

Hospitals are changing their game when it comes to managing those tricky surgical tray sets with specialized rib plates. Instead of waiting until something breaks or randomly replacing parts, they're now spotting potential problems long before they threaten patients. Traditional approaches basically waited around for obvious damage or stuck to arbitrary replacement schedules. But with predictive maintenance, real time data from those little IoT sensors plus detailed wear analysis lets staff catch tiny signs of wear on plating instruments before they become big issues. Think about rib fixation procedures where a failed implant could literally puncture a lung. One bad tray means delaying crucial surgery anywhere between three to five hours while someone scrambles to get replacements sterilized. And money matters too. Hospitals lose around $740,000 each year because of these delays, mostly due to operating room downtime and frantic attempts at cleaning up instruments fast. When facilities start incorporating those predictive alerts right into their Sterile Processing Department routines, they cut down on unexpected tray rejections by almost half. That means rib plates consistently pass both torque tests and surface checks for every operation. The results? Patients benefit directly since hidden micro fractures in plating equipment raise complications after surgery by about 31%. At the end of the day, this isn't merely about keeping trays intact. It's really about stopping unnecessary harm through smarter, more forward thinking management of surgical instruments throughout their entire lifespan.

Core Technologies Enabling Predictive Maintenance in Tray Management

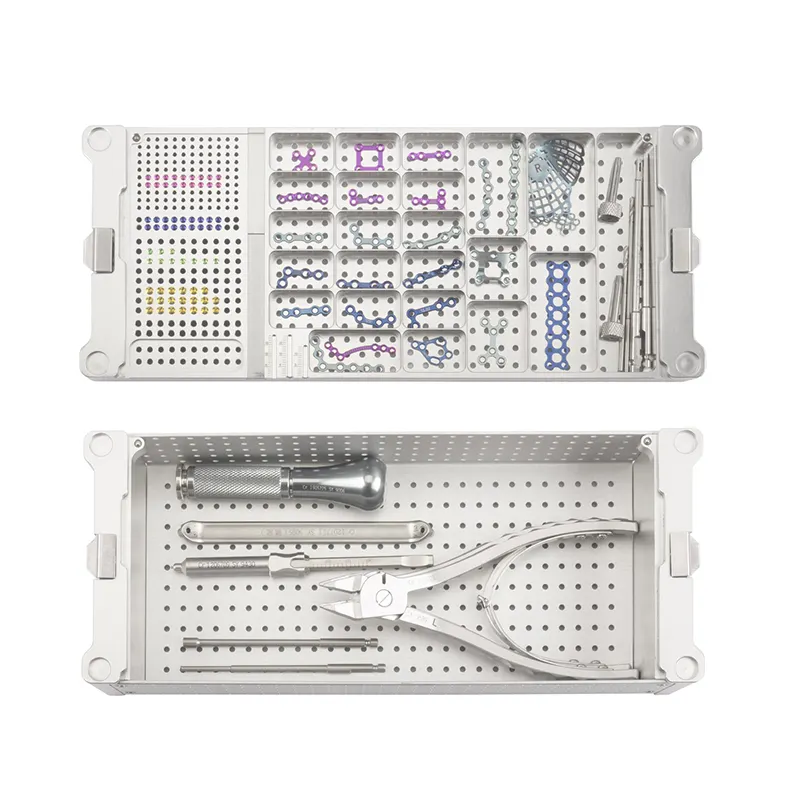

Predictive maintenance transforms surgical tray management by leveraging advanced technologies to prevent instrument failures before they compromise patient safety—particularly critical for specialized instruments like rib plates, which endure high-stress use in trauma surgeries.

IoT Sensors and RFID for Real-Time Tray Usage and Sterilization Tracking

Sensors connected to the Internet of Things along with RFID tags built into medical trays keep tabs on important sterilization factors like temperature levels, pressure readings, and humidity conditions plus how often each tray gets used. When something goes off track during the sterilization process, these monitoring systems catch it right away. They spot problems such as when trays come into contact with harsh chemicals or get exposed to too much heat, both of which can wear down metal parts over time. Hospitals that have implemented this kind of tracking system are seeing around 30 percent fewer instances where they have to pull trays out of service because issues were detected early enough during the cleaning cycle itself.

Wear Analytics and Digital Twins for Predicting Instrument Degradation

Digital twin technology builds virtual copies of actual surgical trays, showing where stress builds up on those rib plates after all that sterilizing and moving around. When paired with AI tools that track wear patterns, these digital models can spot tiny cracks forming and figure out when materials start to weaken. They do this by looking at past performance records alongside what sensors are picking up right now. According to some recent research from clinical engineers in 2023, hospitals using these systems saw about 41% fewer unexpected instrument failures because problems got caught earlier. This means longer lasting trays overall and better adherence to those strict FDA rules about keeping instruments intact and functional.

Implementing Predictive Maintenance in SPD Workflows

Integrating Predictive Alerts into Sterile Processing Dashboard Systems

When hospitals start putting those predictive maintenance algorithms right into their SPD dashboards, it changes everything from just fixing things after they break to actually staying ahead of problems. Technicians get real time warnings as soon as instruments are getting close to breaking down points such as stress fractures in rib plates or worn out hinges, so they can schedule repairs long before anything actually fails. For this setup to work properly, there are basically three main parts needed first. We need those little IoT sensors tracking how often trays get used, then some cloud based software crunching all that sterilization info, and finally those dashboard displays that show what needs attention most urgently. According to some research done on orthopedic trays back in 2024 and published by the Journal of Clinical Engineering, hospitals using this approach cut down on surgery delays caused by equipment issues by around two thirds. Plus, the whole system knows which urgent jobs need doing next and sends them straight to whoever's free among the tech staff. This helps spread out workload better across teams while still keeping everything within those tough AAMI ST79 regulations everyone has to follow.

Validating ROI: Case Evidence of 42% Reduced Tray Rejection at a Level I Trauma Center

A Level I trauma center reduced tray rejection rates by 42% within six months of deploying sensor-based condition monitoring for rib plate sets. By analyzing 12,000+ sterilization cycles and usage patterns, their system predicted instrument degradation with 91% accuracy—slashing emergency reprocessing costs by $740k annually. Key performance improvements included:

| Metric | Pre-Implementation | Post-Implementation | Improvement |

|---|---|---|---|

| Tray rejection rate | 18.7% | 10.8% | 42% reduction |

| Emergency reprocessing costs | $1.76M/year | $1.02M/year | $740k saved |

| Plate replacement frequency | Quarterly | Biannually | 50% decrease |

This evidence confirms that predictive protocols significantly extend instrument set lifecycle management while delivering measurable ROI through optimized surgical kit maintenance. Trauma centers using these systems report 31% fewer delayed surgeries due to instrument availability issues.

FAQ

What is predictive maintenance in surgical trays?

Predictive maintenance for surgical trays uses real-time data and advanced technologies to identify and address potential issues before they cause problems, improving efficiency and patient safety.

How do IoT sensors and RFID help in tray management?

IoT sensors and RFID track sterilization factors such as temperature, pressure, and usage, allowing for early detection of issues that might cause wear and tear on trays.

What technologies are used in predictive maintenance?

Technologies like IoT sensors, RFID, wear analytics, and digital twin models are used to predict instrument degradation and prevent failures.

How does predictive maintenance affect ROI in hospitals?

Predictive maintenance reduces emergency reprocessing costs, tray rejection rates, and surgery delays, providing significant cost savings and extending the lifespan of surgical instruments.

EN

EN

FR

FR

ES

ES

AR

AR