Ensuring Patient Safety and Material Biocompatibility Through ISO 13485

ISO 13485 certification for medical device material suppliers: A foundation for patient safety

The ISO 13485 standard creates what many call a risk-focused quality system that's pretty much required for anyone supplying materials for medical devices. The standard requires written proof at each step of production, starting from where they get the raw stuff all the way through to those final tests. This helps maintain consistent compatibility with body tissues using standards like USP Class VI testing. What this whole process does is stop bad reactions inside patients bodies, things like inflammation or toxic effects. Plus it makes tracking products much easier so companies can quickly find and fix problems if something goes wrong. When we talk about cranio-maxillofacial implants specifically these are parts that actually touch nerves, blood vessels, and bone tissue deep in the skull and face area. For these kinds of implants, following ISO 13485 isn't just good practice it's absolutely necessary. Without this strict approach, there's a real risk of serious issues down the road including infections, implant rejection by the body, or even structural failures that could endanger lives.

How ISO 13485 ensures material consistency and biocompatibility in cranio-maxillofacial (CMF) implant applications

For craniofacial implants, getting both the biomechanics right and ensuring proper biological integration is absolutely essential. The ISO 13485 standard really pushes manufacturers to implement strict statistical process controls. These controls make sure there's consistency across batches when working with materials like titanium alloys and those high performance polymers we see so much of lately, particularly PEEK. And this matters a lot for custom made implants tailored specifically for individual patients. Companies need to test out their sterilization techniques thoroughly and monitor how these materials break down over time when exposed to conditions similar to what happens inside the human body. Speaking of materials, suppliers have to meet certain standards too. Raw materials must pass ASTM F136 tests for titanium and ASTM F1295 for cobalt chromium alloys. This helps confirm they won't crack under stress or corrode prematurely. Regular factory inspections plus robust systems for fixing problems as they arise help cut down on any inconsistencies that might interfere with bone integration. After all, even tiny measurement errors at the sub millimeter level can mean big differences in how well someone recovers functionally after surgery and whether the final appearance looks natural or not.

Regulatory Compliance and End-to-End Supply Chain Control for CMF Implant Materials

Regulatory Requirements for Implantable Devices: The Importance of Supplier Qualification and Traceability

For medical implant makers, following FDA 21 CFR Part 820 along with ISO 13485:2016 isn't optional but necessary. These standards require solid quality control systems that track everything from start to finish and make sure all suppliers are properly vetted. The latest Medical Device Vigilance Report for 2023 shows something alarming though. Almost half, around 48%, of recalled implants came back to problems with parts from suppliers that weren't properly checked out. That's why certified material suppliers under ISO 13485 have developed ways to track materials both forward and backward through the production chain right down to specific patient implants. They also do thorough checks on their own suppliers who handle these certified materials. And they keep detailed records on how things get sterilized and tested for composition in real time throughout manufacturing.

Supply Chain Management Under ISO 13485: Ensuring Control From Raw Materials to Final Implant

ISO 13485 transforms supply chains into tightly controlled ecosystems, where each batch of titanium alloy or PEEK polymer is tracked through manufacturing, processing, and distribution. The standard enforces:

| Control Stage | ISO 13485 Requirement | Impact on CMF Implants |

|---|---|---|

| Raw Material Sourcing | Validated supplier qualifications | Ensures biocompatibility and mechanical reliability of inputs |

| Production | Process validation & environmental controls | Prevents particulate contamination and metallurgical defects |

| Distribution | Sterility maintenance protocols | Reduces post-operative infection risks and preserves functional integrity |

This end-to-end oversight is especially vital for patient-specific CMF implants, where dimensional accuracy and surface fidelity directly influence surgical fit, bone integration, and long-term stability. Relying on non-certified suppliers exposes manufacturers to regulatory enforcement actions—non-compliance penalties averaged $740,000 in 2023 (MedTech Compliance Digest).

Material Selection and Quality Management in Certified CMF Implant Production

Why certified raw materials matter: Material choice and composition for cranio maxillofacial implants

Choosing the right materials makes all the difference for successful CMF implants. Medical grade titanium alloys and PEEK need to go through rigorous testing for biocompatibility and composition checks before they can be used. These tests help avoid problems like inflammation or unexpected mechanical failures. Research shows that when non-certified materials are used instead, there's about an 18% higher chance of implant rejection mainly because of unknown impurities or incorrect alloy compositions. Top suppliers certified under ISO 13485 keep track of every component from source to finished product. They follow ASTM standards F136 and F1295 not just for strength and durability but also how well the material stands up against corrosion inside the body. For craniofacial surgeries specifically, having this kind of material reliability matters a lot since these implants interact directly with very delicate tissues in critical areas of the face and skull.

Manufacturing processes and quality control for patient-specific implants under ISO 13485

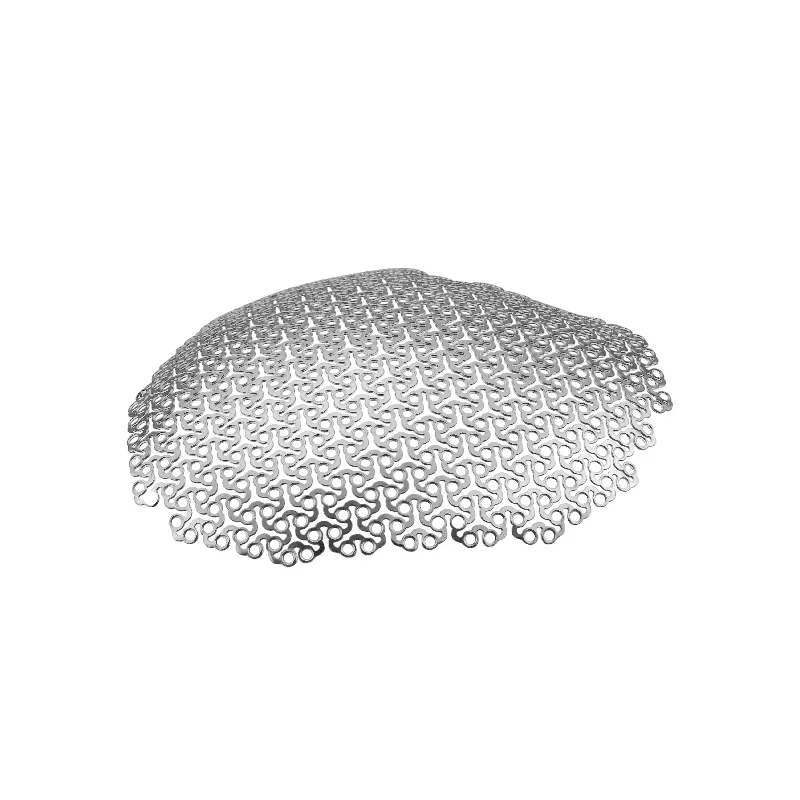

The ISO 13485 standard demands comprehensive quality management systems specifically tailored for craniofacial implants made to fit individual patients. Statistical process control needs to be woven into every stage from computer numerical control machining right through to 3D printing and post-processing steps. Getting those dimensions just right matters a lot too - we're talking about keeping them within plus or minus 0.05 millimeters. Monitoring cutting conditions as they happen helps avoid problems like heat damage or structural issues in the porous parts that actually promote bone integration. When it comes time to validate everything works properly, manufacturers run non-destructive tests looking for hidden defects, check surface finish stays below 0.8 microns roughness average, and confirm materials can handle the sterilization process without breaking down. All these careful checks make sure the final product fits the person's skull shape perfectly while still passing all the regulatory hurdles regarding consistent materials, reliable performance, and complete documentation throughout production.

Addressing Industry Challenges: Are All Biomaterial Suppliers Held to the Same ISO 13485 Standards?

Controversy analysis: Variability in supplier accountability and enforcement of ISO 13485 in the biomaterials market

ISO 13485 is supposed to cover all medical device material suppliers according to the standards, but how it gets enforced around the world varies quite a bit. Recent checks done by one major European certification organization showed that just about 34 percent of companies supplying materials for craniofacial implants actually get their compliance reviewed every year. The problem stems from different ways countries interpret risk management requirements. Some regulatory bodies focus more on validating manufacturing processes rather than tracking where raw materials come from, which goes against what ISO 13485 really wants - complete quality control throughout the whole supply chain. These differences create problems later on when making sure implants work properly, especially regarding things like how much metal ions might leach out over time or how fast certain plastics break down inside the body. When there's no consistent way of enforcing these rules across borders, we end up with markets split up by region, and patients undergoing facial reconstructions face real safety concerns because of this. Getting everyone to apply ISO 13485 consistently remains important if we want to keep delivering medical materials that are both safe and actually work as intended.

FAQ

Why is ISO 13485 important for cranio-maxillofacial implants?

ISO 13485 ensures the safety and compatibility of materials used in cranio-maxillofacial implants, preventing adverse reactions and ensuring proper integration with body tissues.

What materials are commonly used for CMF implants under ISO 13485?

Materials like titanium alloys and high-performance polymers, particularly PEEK, are commonly used for CMF implants due to their biocompatibility and mechanical reliability.

How does ISO 13485 affect the supply chain of medical device materials?

ISO 13485 transforms supply chains into controlled ecosystems, ensuring each batch of materials is tracked throughout manufacturing, processing, and distribution to ensure quality and safety.

Are all biomaterial suppliers held to the same ISO 13485 standards globally?

No, enforcement of ISO 13485 varies globally, leading to inconsistencies in supplier accountability and potential risks in implant safety.

Table of Contents

- Ensuring Patient Safety and Material Biocompatibility Through ISO 13485

- Regulatory Compliance and End-to-End Supply Chain Control for CMF Implant Materials

- Material Selection and Quality Management in Certified CMF Implant Production

- Addressing Industry Challenges: Are All Biomaterial Suppliers Held to the Same ISO 13485 Standards?

- FAQ

EN

EN

FR

FR

ES

ES

AR

AR