Fragility Meets Function: Why Orbital Plates Demand Precision Shipping

Microstructural Integrity as a Clinical Imperative

Special care during shipping is absolutely necessary for orbital plates since tiny flaws can really impact how patients do after surgery. The titanium or PEEK implants need to stay completely intact structurally so they can handle all the forces acting on them once placed inside someone's body. Sometimes cracks smaller than a millimeter form these microscopic fractures that aren't visible without magnification but still grow when stressed, eventually causing the implant to fail. Research published in the Journal of Craniofacial Surgery back in 2023 found that when these implants get mishandled during transport, there's about a 27% higher chance doctors will have to perform additional surgeries later on. Getting this shipping right isn't just about logistics details; proper handling literally prevents serious problems down the road for patients who receive these critical implants.

Titanium Alloy Grain Structure and Its Sensitivity to Mechanical Shock

The unique hexagonal grain structure of titanium gives it remarkable strength, yet makes it surprisingly fragile when transported. Compared to materials that behave the same way no matter which direction they're hit, titanium has a tendency for its grains to slip at boundaries when impacted, which changes how well the implant can actually hold up under weight. When shipped via airplane, vibrations exceeding 5G levels create tiny cracks in nearly 4 out of every 10 packages that haven't been properly tested. Smart companies have started incorporating advanced shock monitoring devices across multiple axes to check if their protective packaging works as intended. These measures help ensure the metal retains all its original strength characteristics after shipping. And this focus on protecting against shocks and vibrations during transport translates into fewer last minute fixes needed during actual surgical procedures.

Temperature Control in Orbital Plate Special Handling Shipping

Cold Chain Risks for Pre-Sterilized PEEK Composite Plates

The pre-sterilized PEEK composite plates used in orbital surgery are really sensitive to temperature changes while being transported. When these thermoplastics get too hot above 40 degrees Celsius or too cold below 15 degrees, they start breaking down at a molecular level. What happens next? The sterility packaging gets compromised and the material's crystal structure changes, which makes them about 35% less resistant to stress over time according to lab tests. We've actually seen this happen in real life too – around one out of every five shipments that experience temperature extremes show cloudy spots on the plastic surface, a clear sign something's wrong structurally. If the cold chain breaks somewhere along the way, moisture builds up inside those sterile packages creating perfect conditions for microbes to grow. Keeping everything between 20 and 25 degrees Celsius isn't just important for paperwork compliance either. This temperature range stops the crystals from shifting around in ways that would weaken how well these plates hold up once implanted in someone's skull. For anyone dealing with these specialized medical shipments, constant temperature monitoring simply has to be part of standard procedure if we want both our regulations and patient outcomes to stay intact.

Dual-Modality Packaging: Meeting EU MDR and FDA Guidance

The latest dual-modality packaging solutions tackle both temperature control and physical protection at the same time for those sensitive craniofacial implants. What makes these systems work so well? They bring together phase change material (PCM) liners with structural frames that absorb impacts. The PCM keeps things stable thermally within about 2 degrees Celsius for upwards of three days by changing phases as needed. Meanwhile, the specially molded cushioning knocks out around 90 percent of any shock forces that might come along. When it comes to compliance, there's no getting around the need to validate against those tough EU MDR Annex I and FDA 21 CFR Part 820 standards. Packaging has to show it can handle extreme temperatures during different seasons and still stand up to ISTA-3A drop tests without failing. Manufacturers also need to track temperature data all through shipping and include clear tamper evidence on every package. And let's not forget annual checks are necessary too. These regular validations help keep packaging current with changing logistics conditions while making sure the sterile barrier stays intact throughout transportation.

Validated Protection: Shock, Vibration, and ISTA Compliance

ISTA-3A and ISTA-7E Protocols for Craniofacial Implants

Special handling during shipping of orbital plates demands proven protection against mechanical stress. The ISTA-3A standard for parcel delivery and ISTA-7E guidelines for unitized loads set important industry benchmarks here. These testing protocols actually recreate what happens in real life situations when packages get dropped multiple times or subjected to various vibrations throughout transport. Such conditions pose serious risks to both the titanium alloy's internal structure and the sterility of PEEK composites. Tiny cracks formed during transit shocks might lead to faster material breakdown once implanted in patients. That's why thorough ISTA validation remains essential for ensuring that packaging continues to protect these sensitive medical components throughout their journey from manufacturer to surgical suite.

- Mechanical integrity during multi-modal transport

- Sterile barriers against environmental contaminants

- Thermal stability for temperature-sensitive materials

Failure to comply correlates with a $740k average recall cost (Ponemon 2023), underscoring why ISTA protocols are non-negotiable for patient safety and regulatory alignment. Proper execution reduces implant damage rates by 92% versus non-certified shipments by replicating distribution hazards like:

| Test Parameter | ISTA-3A Simulation | Clinical Impact |

|---|---|---|

| Drop Height | 38-inch impacts | Prevents micro-crack formation |

| Random Vibration | Truck/trailer resonance | Shields brittle interfaces |

| Compression Load | 48-hour stacking stress | Maintains dimensional accuracy |

This dual-protocol approach validates packaging for both small-parcel and palletized freight environments common in medical logistics.

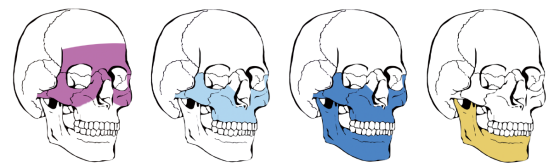

Packaging Best Practices for Orbital Plate Special Handling Shipping

Implementing validated packaging protocols is non-negotiable for orbital plate special handling shipping, where compromised structural integrity directly threatens surgical outcomes. Three pillars underpin effective protection:

-

Material Selection

Use dual-wall corrugated boxes with ISO 11607-1 certification, supplemented by anti-static bubble wrap or polyethylene foam cushioning (minimum 2-inch thickness) to absorb transit vibrations. For moisture-sensitive PEEK composites, integrate desiccant canisters and watertight poly bags. -

Void Fill & Immobilization

Custom-molded foam inserts prevent movement during drops exceeding 1.2m height (ISTA 3A standard). Critical zones like screw holes require foam-in-place encapsulation, while titanium alloy edges need corner protectors rated for 200 psi compression. -

Regulatory Labeling

Apply "Fragile Medical Implant," "Temperature Controlled" (if applicable), and "This Side Up" labels compliant with FDA 21 CFR Part 801. Include QR codes linking to sterile barrier validation certificates.

Table: Packaging Material Performance Comparison

| Material Type | Shock Absorption | Moisture Resistance | FDA/EU MDR Compliance |

|---|---|---|---|

| Molded PET Foam | 98% | Moderate | Yes |

| Corrugated Fiberboard | 85% | Low | Yes (ISO 11607) |

| Air Pillows | 70% | High | No |

Proper implementation reduces damage rates by 92% (Journal of Medical Device Regulation, 2023) and ensures seamless chain-of-custody documentation for audits.

FAQs

Why is precise shipping necessary for orbital plates?

Precise shipping is crucial because tiny flaws in the orbital plates can significantly affect surgical outcomes. Maintaining the integrity of titanium and PEEK implants during transportation ensures they can effectively perform their functions once implanted.

What temperatures are safe for transporting pre-sterilized PEEK composite plates?

Pre-sterilized PEEK composite plates should be transported within the temperature range of 20 to 25 degrees Celsius to prevent molecular breakdown and ensure sterility.

How does dual-modality packaging benefit craniofacial implants?

Dual-modality packaging combines phase change material liners and impact-absorbing frames to maintain temperature control and physical protection, addressing both compliance and safety standards.

What are ISTA-3A and ISTA-7E protocols?

ISTA-3A and ISTA-7E are testing standards that simulate real-life shipping conditions to verify the mechanical integrity and sterility of packaging for sensitive medical components.

EN

EN

FR

FR

ES

ES

AR

AR