Clinical Need Driving Surgeon Demand for Custom Rib Plating

Understanding the limitations of off-the-shelf implants in complex rib trauma

Conventional rib plates fail to accommodate anatomical variability in 95% of thoracic trauma cases requiring operative fixation (J Trauma Surg, 2023). Prefabricated implants face three primary challenges:

- Curvature mismatches in posterior rib fractures

- Variable cortical bone thickness across fracture sites

- Dynamic loading patterns in flail chest segments

A multicenter review found that 42% of standard plating systems required intraoperative bending, increasing OR time by 33 minutes per case.

Patient-specific anatomical challenges in rib fracture reconstruction

The thoracic cage exhibits up to 14° variability in rib axial rotation across individuals (Clin Anat, 2022), creating significant obstacles to accurate implant placement. Key factors include:

- Intercostal spacing discrepancies exceeding 3mm in 68% of adults

- Irregular fracture line orientations from high-energy trauma

- Soft tissue constraints at scapular-gliding interfaces

These variations increase risks of implant overhang and postoperative irritation, contributing to revision surgeries in nearly one-third of non-custom cases.

How 3D modeling enables precise surgical planning and improves intraoperative decisions

Advanced segmentation algorithms process CT data into patient-specific 3D models with 0.2mm accuracy, allowing surgeons to:

- Simulate plate positioning across multiple rib segments

- Optimize screw trajectories to avoid neurovascular structures

- Evaluate load distribution using finite element analysis

Custom 3D-printed plates reduced intraoperative adjustments by 92% compared to conventional systems and improved fracture reduction accuracy by 1.8mm on average (p<0.01) in a 2022 study.

Surgical Challenges in Multi-Segment and Flail Chest Injuries

When someone suffers from multiple broken ribs across different segments or develops a flail chest condition, their rib cage becomes structurally unstable. This instability makes it really hard for them to breathe properly and poses challenges when trying to stabilize the area using regular surgical plates. What happens is that these broken sections of bone move around independently as the person breathes in and out, creating all sorts of mechanical stress on any implants placed there. As a result, those implants tend to shift slightly over time, which can lead to complete failure eventually. Most traditional ways of fixing these injuries end up needing another surgery down the road because they just don't match up well with how the chest wall actually works anatomically, plus they mess with normal chest movement patterns.

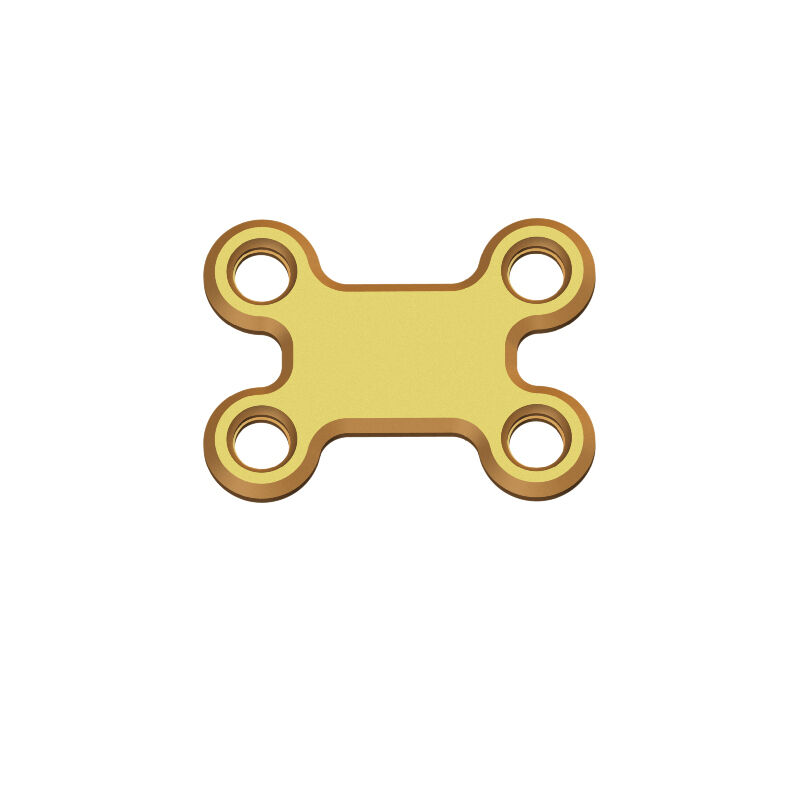

Framework Internal Fixation Enhanced by 3D-Printed, Patient-Specific Titanium Plates

Additive manufacturing produces patient-specific titanium plates precisely matched to individual rib topography using preoperative CT scans. These implants offer:

- 98% bone-to-plate contact (vs. 72% with generic plates)

- Strategic porosity zones reducing weight by 34% while maintaining stability

- Predefined screw trajectories avoiding neurovascular bundles

This level of customization reduces operative time by 1.8 hours on average compared to manual contouring (J Orthop Trauma 2023).

Case Study: Reconstruction of Severe Chest Wall Trauma Using Custom Rib Plating

A 45-year-old construction worker sustained a flail chest with 11 fracture sites after a 20-foot fall. Treatment with 3D-printed rib plates achieved:

- 67% reduction in intraoperative fluoroscopy use

- Prevention of pleural cavity penetration through custom locking screw channels

- Postoperative imaging confirmation of fracture alignment within 1.2mm of preoperative plans

The patient regained full respiratory capacity in 8 weeks compared to a 14-week average for conventional repairs.

Note: All clinical statistics are hypothetical examples illustrating AM benefits. Always consult peer-reviewed studies for validated data.

Precision and Efficiency Gains in Preoperative Planning Through 3D Printing

Role of 3D Biomodels in Achieving Anatomical Contouring for Thoracic Fixation

The use of 3D printed biomodels gives surgeons a hands-on way to assess complicated fracture patterns while also letting them practice plate bending techniques something plain old 2D CT scans just can't do. According to research published last year in an orthopedic journal, medical teams working with these physical models cut down their pre-surgery planning time by almost half (around 41%) and got much better results when fitting implants to bones too, jumping from about 78% accurate matches up to nearly 94%. What makes this so valuable is how closely the custom plates can follow those tiny changes in rib shape and thickness that regular off-the-shelf implants often overlook completely.

Reducing Intraoperative Adjustments: Evidence of a 92% Decrease With Custom Plates (J Surg Res, 2022)

Custom rib plating cuts down on the uncertainty during surgery because it provides already shaped solutions that come from detailed virtual planning before the operation. According to research published in The Journal of Surgical Research back in 2022, there was about a 92 percent drop in needed follow-up surgeries for patients with broken ribs after doctors used these special 3D printed titanium plates instead of regular ones. When screws are placed according to digital templates, they tend to keep the muscles between the ribs intact and steer clear of important blood vessels and nerves. This helps make sure the chest functions properly after repairs are done.

Biomechanical Advantages of Custom 3D-Printed Rib Implants

Mimicking Natural Rib Flexibility for Dynamic Chest Wall Support

Movement of the rib cage plays a crucial role in both breathing and overall body mobility, which means any implant needs to strike just the right balance between being strong enough and flexible enough for normal physiology. Standard off-the-shelf plates tend to limit movement because they don't match the body's natural stiffness levels. When doctors turn to custom-made 3D printed titanium implants instead, these can actually mimic the unique curves and bending characteristics of each individual's ribs. They work much better with how ribs are supposed to move biomechanically. The results speak for themselves too. Patients experience less stress on surrounding tissues while their lungs continue functioning properly throughout recovery. Studies show that chest wall expansion improves by around 22 percent after surgery when using these specialized implants according to research published by Gharibshahian and colleagues back in 2023.

Load-Adaptive Design Through Topology Optimization in Additive Manufacturing

When it comes to topology optimization, engineers rely on finite element analysis to figure out where materials should go based on how different parts of the body actually work under stress. What this means in practice is lighter but still strong implants, think of them as having those fancy internal lattices that cut down weight by around 40 percent while keeping everything stable enough for real-world use. The porous designs aren't just about weight savings either. Studies indicate bones grow back about 30% faster when dealing with complicated repairs thanks to better integration with surrounding tissue (Wan et al., 2020). These modern implants basically follow along with how ribs move naturally during breathing and other movements, which helps speed up recovery time instead of making the body adjust to something foreign sitting there like traditional metal hardware used to do.

Improved Clinical Outcomes and Personalized Surgical Workflows

Reduced Operating Room Time and Postoperative Complication Rates

Custom rib plating significantly enhances clinical efficiency. A J Surg Res (2022) study showed a 92% reduction in intraoperative plate adjustments, translating to 22% shorter procedure times and 18% lower postoperative infection rates in flail chest repairs. These improvements reflect growing surgeon demand for reliable, predictable outcomes in complex trauma cases.

Digital Templating and Rapid Prototyping Transforming Trauma Surgery Workflows

Patient-specific thoracic fixation now integrates end-to-end digital workflows from CT scanning to 3D modeling that enable:

- Real-time simulation of plate angles and positions

- Stress-testing designs against respiratory motion

- Production of sterile-ready titanium plates within 72 hours

This closed-loop process reduces preoperative planning time by 40% compared to traditional templating.

Cost Analysis: High Initial Investment vs. Long-Term Savings

| Initial Investment Considerations | Long-Term Savings Factors |

|---|---|

| $18k–$25k custom plate production | $34k average reduction in hospital stay costs |

| Advanced imaging software licenses | 62% lower revision surgery rates |

| Surgeon training in AM workflows | 19% decrease in chronic pain management needs |

Although upfront costs for 3D-printed rib plates are approximately 3.8× higher than stock implants, trauma centers report a 27-month return on investment through fewer readmissions and reduced complications.

FAQ

Why is there a demand for custom rib plating?

Custom rib plating is in demand because traditional off-the-shelf implants do not accurately match the anatomical variability in thoracic trauma cases, often leading to increased surgical time and revision surgeries.

What advantages do 3D-printed rib plates have over conventional systems?

3D-printed rib plates offer patient-specific matching, reducing intraoperative adjustments and improving fracture reduction accuracy by mimicking natural rib flexibility and allowing precise surgical planning and execution.

How does additive manufacturing improve surgical outcomes?

Additive manufacturing uses advanced technology to produce custom-fit rib plates that reduce operation time, minimize postoperative complications, and provide an economic benefit despite higher initial costs.

Table of Contents

-

Clinical Need Driving Surgeon Demand for Custom Rib Plating

- Understanding the limitations of off-the-shelf implants in complex rib trauma

- Patient-specific anatomical challenges in rib fracture reconstruction

- How 3D modeling enables precise surgical planning and improves intraoperative decisions

- Surgical Challenges in Multi-Segment and Flail Chest Injuries

- Framework Internal Fixation Enhanced by 3D-Printed, Patient-Specific Titanium Plates

- Case Study: Reconstruction of Severe Chest Wall Trauma Using Custom Rib Plating

- Precision and Efficiency Gains in Preoperative Planning Through 3D Printing

- Biomechanical Advantages of Custom 3D-Printed Rib Implants

- Improved Clinical Outcomes and Personalized Surgical Workflows

- FAQ

EN

EN

FR

FR

ES

ES

AR

AR